UC:IS:RailInspectionData: Difference between revisions

| [checked revision] | [checked revision] |

(beautified table) |

(+interwiki) |

||

| Line 92: | Line 92: | ||

{{UC references}} | {{UC references}} | ||

''None'' | ''None'' | ||

{{interwiki}} | |||

Revision as of 12:07, 23 September 2024

| Rail Inspection Data (RIND) Subschema: Infrastructure Reported by: DZSF & ZEDAS | |||

| |||

| For general information on use cases see UC:Use cases |

Use case / Anwendungsfall

Rail Inspection Data ; Schienenprüfdaten

Description / Beschreibung

The application broaches the issue of railway track inspection and maintenance. With the help of railML data, relevant information on the rail inspection runs and the identified defects as well as their location in the rail network will be assembled and visualised. For this purpose, railML infrastructure data is to be supplemented with basic information on the type, extent, and localization of the rail defects as well as linkages to the corresponding inspection reports and images in the inspection data management system.

This is intended to link the existing separate data and reporting systems of the operators involved.

- Storage of inspection data recorded by the rail examination train,

- Annotations of the assumed defects supplemented by the evaluators,

- Findings and report of the affected track segments stated by the on-site inspectors.

By means of a railML-based interface, access is to be made possible for other linked sectors as

- Deployment systems for the scheduling of ad hoc traffic requests (track capacity reductions due to blocking phases for maintenance and speed restriction sections),

- Planning of the required maintenance measures (defect type, error degree, date of report),

- Operational planning of the rail examination trains (time of last inspection of track segments).

Data Flows and Interfaces / Datenflüsse und Schnittstellen

There are different data flow applications related to inspection runs and inspection events (defects):

| 1 | Import inspection runs | All inspection runs for a selected period or selected routes/tracks (and sections?) are to be listed. |

| 2 | Retrieve information about inspection runs | For a selected list of inspection runs, detailed information and associated DICONDE files (including download path) for the individual runs are returned. |

| 3 | Import of inspection events/inspection anomalies | Recorded inspection events/inspection anomalies are to be listed for a selected period or selected routes/tracks (and sections?) or for a selected inspection run. |

| 4 | Retrieve information about inspection events/inspection anomalies | For a selected list of inspection events, detailed information, status, and associated DICONDE files (including download path) for the individual events are returned. |

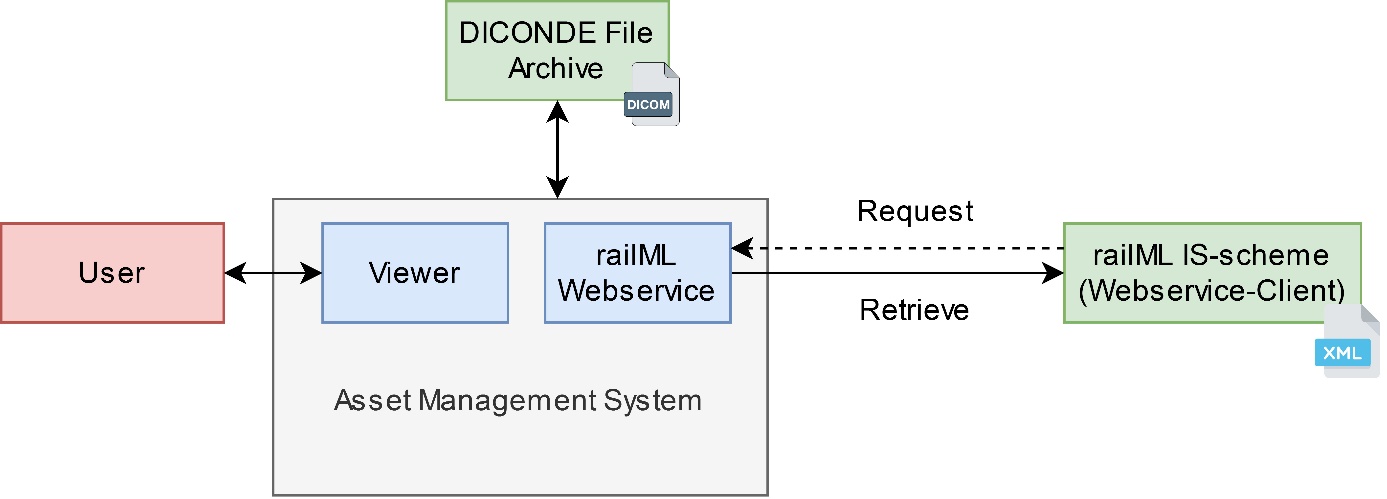

The data flow is bi-directional. Applications 1 and 3 provide basic information about inspection runs and events from the Asset Management System to the railML file. Detailed material described in applications 2 and 4 can be accessed via requests generated with data in the railML file. The Asset Management System provides the requested material from the relevant DINCONDE files where inspection images and reports are stored.

Data for applications 1 and 3 are exchanged daily and are of low complexity (basic information). For applications 2 and 4, the frequency and complexity of data transfer depend on the specific requests. Large requests can lead to medium complexity.

Dependent railML® domains / Abhängige railML®-Domänen

Infrastructure, essential for the localization of defect events in the railway network.

Characterizing Data / Charakterisierung der Daten

The following table describes the data (defect attributes) exchanged in the above data flow applications.

| Element | Attribute | Typical value |

|---|---|---|

| track | track number on which the defect was found | 6345 |

| milage | milage/track kilometre on which the defect occurs | 19.243 |

| geo coordinate | geo coordinates of the location of the defect occurrence | (51.277457, 13.519865) |

| type | type of the defect | HeadCheck |

| error class | error class of the defect according to the rail failure catalogue and type of defect | F3 |

| length | length of the defect | 2.2 cm |

| depth | depth of the defect | 3.2 mm |

| inspection run | inspection run on which the defect was registered | 137 |

| date | date of report | 18.08.2023 |

Sub-use cases / Teil - Usecases

None

Additional remarks / Zusätzliche Bemerkungen

None

References / Verweise

None